Project Introduction

The drop test is divided into packaging drop and bare metal drop. Packaging drop mainly considers the product's ability to resist unexpected drop impacts during transportation and storage; bare metal drop mainly considers the product's ability to resist unexpected drop impacts during normal use. The drop of the package can also reflect the ability of the package to protect the product when it is dropped vertically.

The height of the drop, the number of drops and the direction of the drop reflect the severity of the test. For different products, the international standards and specifications of the drop method and drop height requirements are different. For hand-held products (such as mobile phones, MP3, etc.), most of the drop heights are between 100cm ~ 150cm. IEC recommends that for handheld products with ≦ 2kg, the drop height of 100cm should not be damaged, and MIL recommends the drop height It is 122cm. Intel recommends a drop height of 150cm for handheld products (such as mobile phones).

According to the reference standard, the falling surface is a smooth, hard and rigid surface made of concrete or steel, or when necessary, other floors, such as marble floors.

Packaging drop test

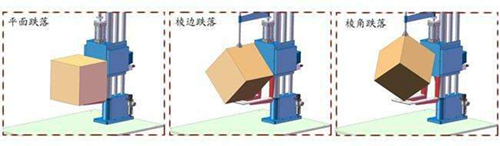

The general requirements for the drop test of the packaging are as follows: the drop method is to drop freely on one corner, three sides and six sides.

Angle drop: After falling, the test angle hits the contact plane;

Side drop: tilt the bottom surface of the model to a horizontal angle of 20°, then raise it to the test height and then drop it, its side impacts the contact plane;

Surface drop: It is necessary to make the test sample directly hit the contact plane after the test sample falls.

When the packaging is dropped, determine whether the strength of the outer box or inner box and the firmness of the product packaging meet the quality requirements.

Bare metal drop test

Purpose of bare-metal drop test

The bare-metal drop test is to detect the ability of the product to resist throwing and dropping during use. The method of releasing the test sample should be such that the test sample can be freely dropped from the hanging position. When releasing, the interference should be minimized.

· ASTM standard test instrument requirements: Throwing ground should be covered with 3.0mm (1/8in) thick rubber floor, at least 64mm (2.5in) thick concrete, and the area should not be less than 3㎡.

· Test equipment requirements of EN71 standard: Throwing ground is 4mm thick steel plate, the surface of the steel plate should be coated with 2mm thick, Shore hardness of 75±5A, and placed on a non-flexible horizontal surface.

· GB6675 standard test instrument requirements: the impact surface should be composed of a vinyl polymer sheet with a rated thickness of about 3mm, the vinyl polymer sheet is attached to concrete with a thickness of at least 64mm, and the surface of the cover should reach Shore hardness A80 degrees 10 The area is at least 0.3㎡.

Method Standard

GB/T2423.8 "Part 2 of Environmental Tests for Electrical and Electronic Products: Test Method Test Ed: Free Fall".

IEC60068-2-32 "Free Fall Test Method".

GB-T4857.5 drop test method for packaging and transportation packages.

ASTM D 5276-98(2009)

Label printers entering the Brazilian market, ANATEL certification is an essential passport! It is the recognition of the Brazilian Telecommunications Authority for the safety and compliance of electronic products, without which products cannot be legally sold.

SRRC certification is not only a guarantee of product compliance, but also a key to opening up the market.

FCC ID certification is a mandatory certification for electronic products by the Federal Communications Commission (FCC) in the United States, and it is essential for label printers to obtain this certification.

The drop test is divided into packaging drop and bare metal drop. Packaging drop mainly considers the product\'s ability to resist unexpected drop impacts during transportation and storage; bare metal drop mainly considers the product\'s ability to resist unexpected drop impacts during normal use.

Get a quote